Forged steel valves

LVSA GROUP compact forged steel valves series consist of gate, globe and check valves, optimized by the most advanced FEA (Finite Element Analysis) design and manufactured in accordance with API 602, EN/ISO 15761 and ASME B16.34. These valves are available in size from NPS 1/2" to 2" in ASME class 150 to 4500.

A wide range of body materials are available including A105, LF2, F11/F22, F5/F9, F304L, F316/L etc.; special service applications valves such as NACE MR 0175 can also be provided. Bolted bonnet is the standard design; threaded, seat-welded or welded bonnet are optional. A complete range of integral flanged end gate, globe and check valves are now provided.

Emission proof: API 624 Type tested valves for fugitive emission (with methane 97%) for both rising and rising & rotating stem valves (under 100 ppmv) equipped with API 622 compliant packings.

Forged steel gate valve

Manufactured in accordance to API - 602 & ASME B16.34

Products Range:

Size: DN 15 - DN 50

Type: Welded bonnet, Bolted Bonnet, integral flanged ends

Pressure Rating: Class 150# to 4500#

Material of Construction: Carbon steel, Alloy steel, Austenitic Stainless steel, Duplex and Super duplex stainless steel, Nickel alloy, Titanium

End Connection: Butt-weld, socket-weld, threaded, screwed

Forged steel globe valve

Manufactured in accordance to API - 602 & ASME B16.34

Products Range:

Size: DN 15 - DN 50

Type: Welded bonnet, Bolted bonnet, y-pattern welded bonnet, integral flanged ends

Pressure Rating: Class 150# to 4500#

Material of Construction: Carbon steel, Alloy steel, Austenitic Stainless steel, Duplex and Super duplex stainless steel, Nickel alloy, Titanium

End Connection Butt-weld, socket-weld, threaded, screwed

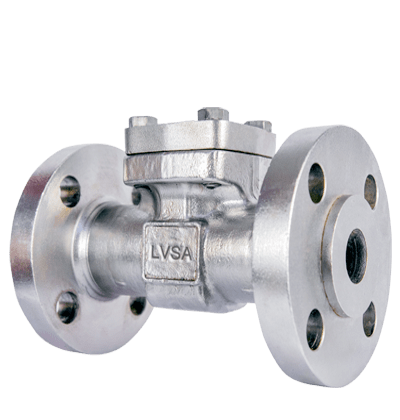

Forged steel check valve

Manufactured in accordance to API - 602 & ASME B16.34

Products Range:

Size: DN 15 - DN 50

Type: Welded bonnet, Bolted bonnet, y-pattern welded bonnet, integral flanged ends

Pressure Rating: Class 150# to 4500#

Material of Construction: Carbon steel, Alloy steel, Austenitic Stainless steel, Duplex and Super duplex stainless steel, Nickel alloy, Titanium

End Connection Butt-weld, socket-weld, threaded, screwed

We at LVSA Group continually strive to meet and exceed the needs of our customers, by paying attention to detail and working with Clients to thoroughly understand their requirements and offer quality products and superior service. Our organization strives to become a model of success and true potential in the growing Global Market. Our highly-qualified staff and partners together with our ISO 9001:2015 Certified system works tirelessly to meet our planned objectives in order to serve you exclusively.

We at LVSA Group continually strive to meet and exceed the needs of our customers, by paying attention to detail and working with Clients to thoroughly understand their requirements and offer quality products and superior service. Our organization strives to become a model of success and true potential in the growing Global Market. Our highly-qualified staff and partners together with our ISO 9001:2015 Certified system works tirelessly to meet our planned objectives in order to serve you exclusively.